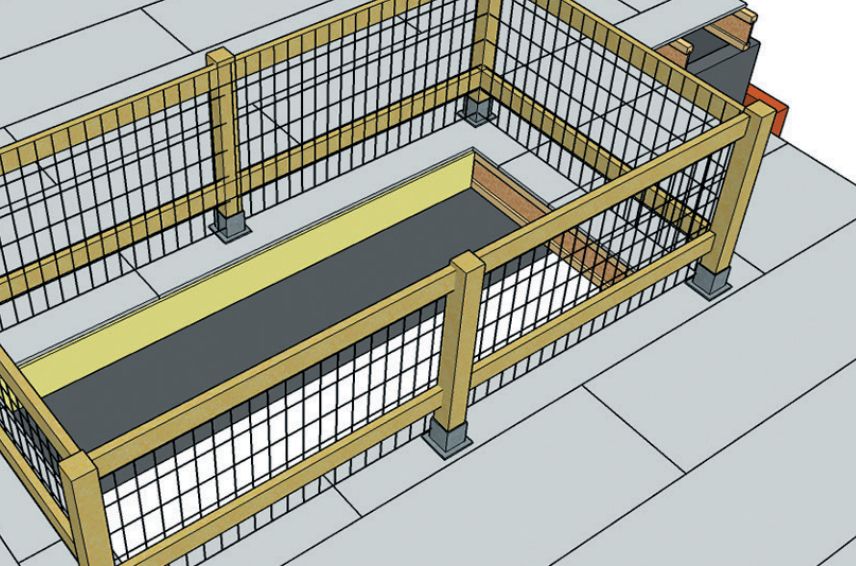

Open & Guarded

No loads applied, Scaffold standards to run continuous through opening.

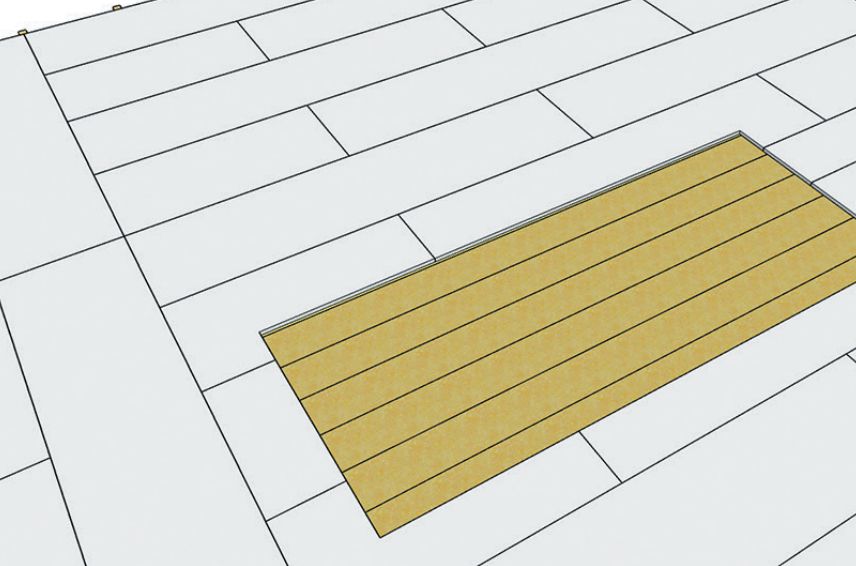

Sacrificial Joists & Decking

Full loads can be applied to the opening area.

WellSafe™ Frame

Operatives and scaffold standards only, over the opening area.

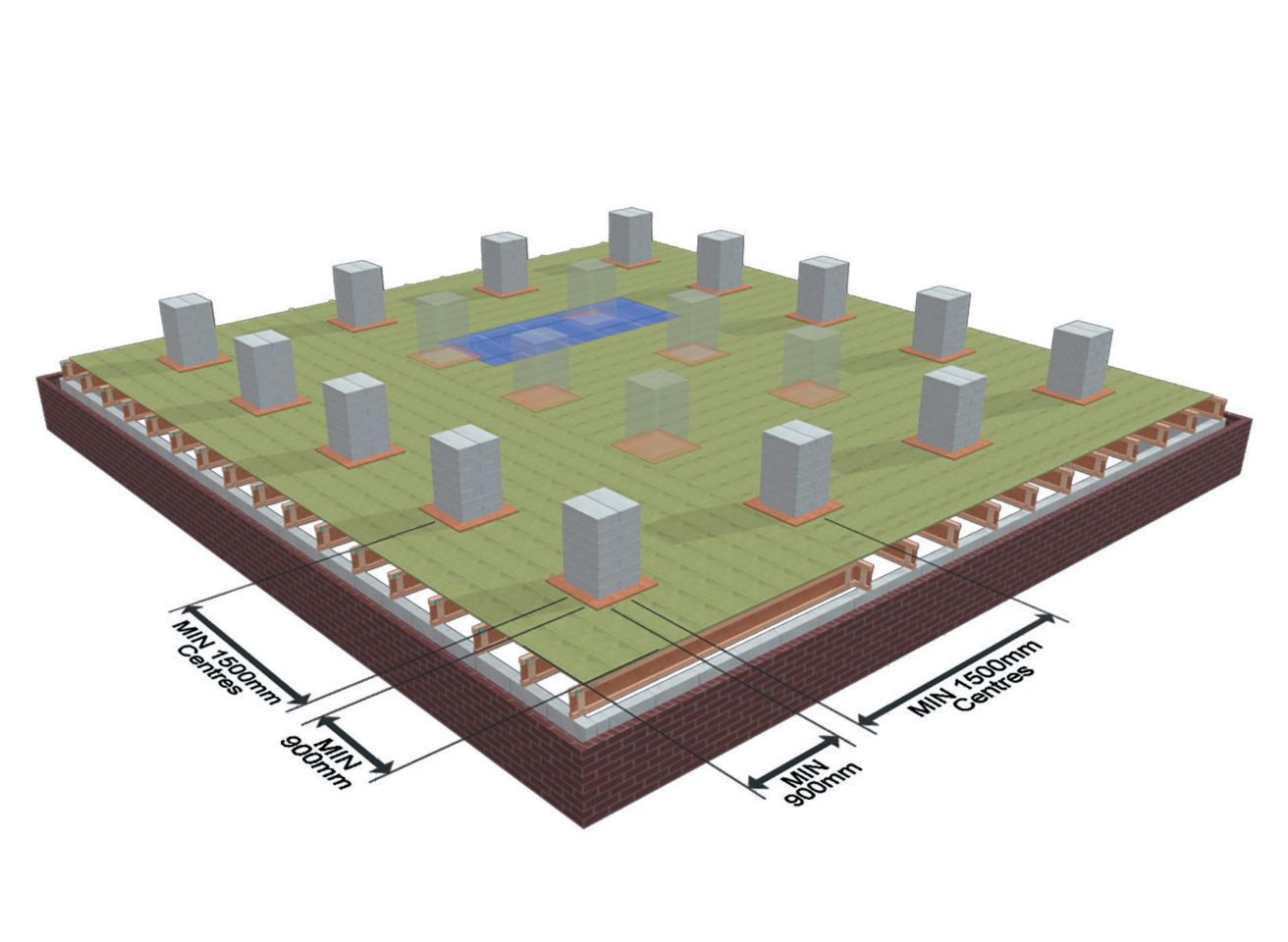

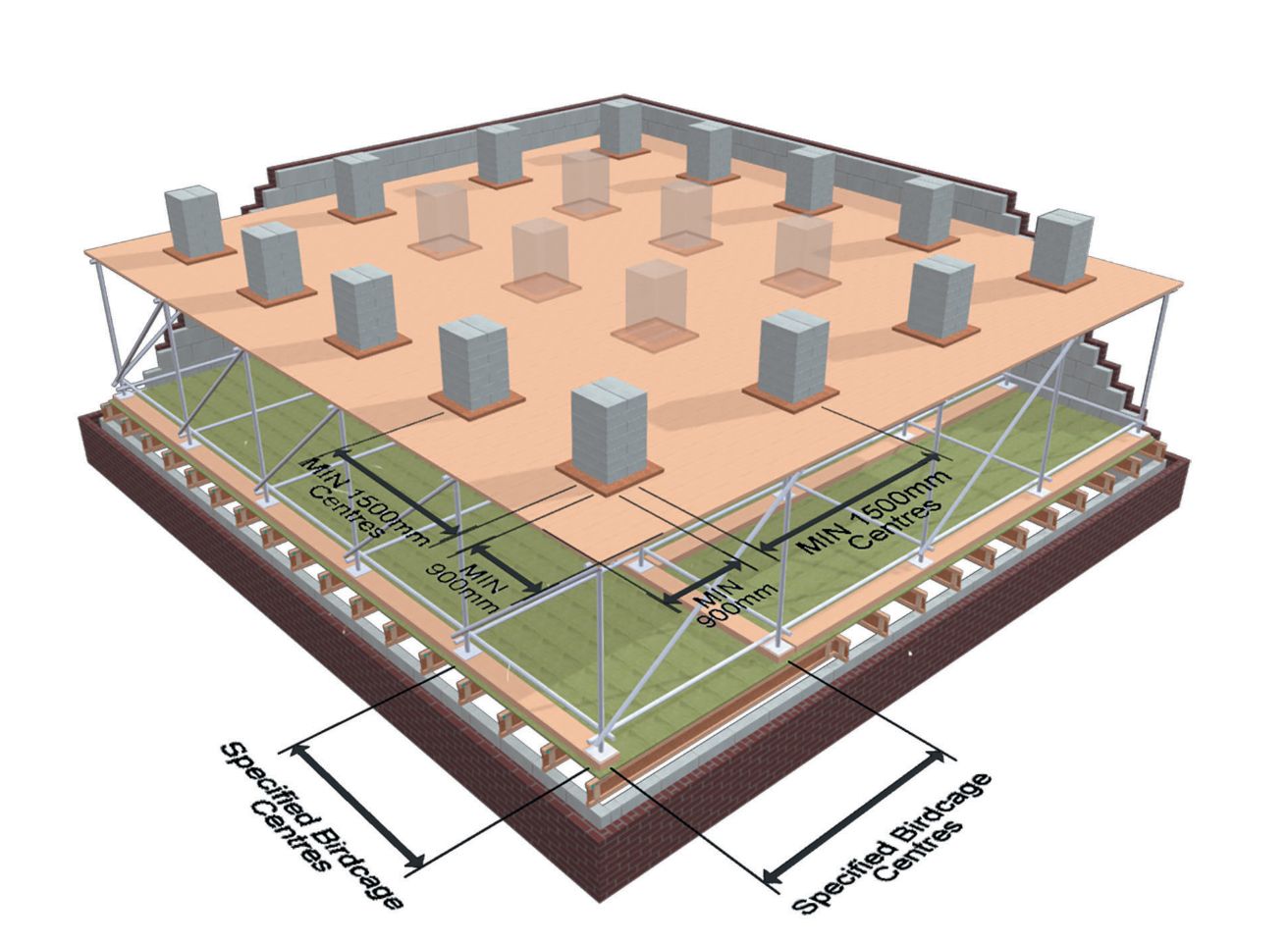

Blockwork must be loaded out in 450mm x 450mm stacks, on timber pattresses at no less than 1.5m centres and at least 900mm from external walls. Each stack must contain max 14 No. blocks.

Where block stack loads are applied to the floor via a scaffold system, all scaffold standards must sit on double 38 x 225mm scaffold boards spanning perpendicular to the joists.

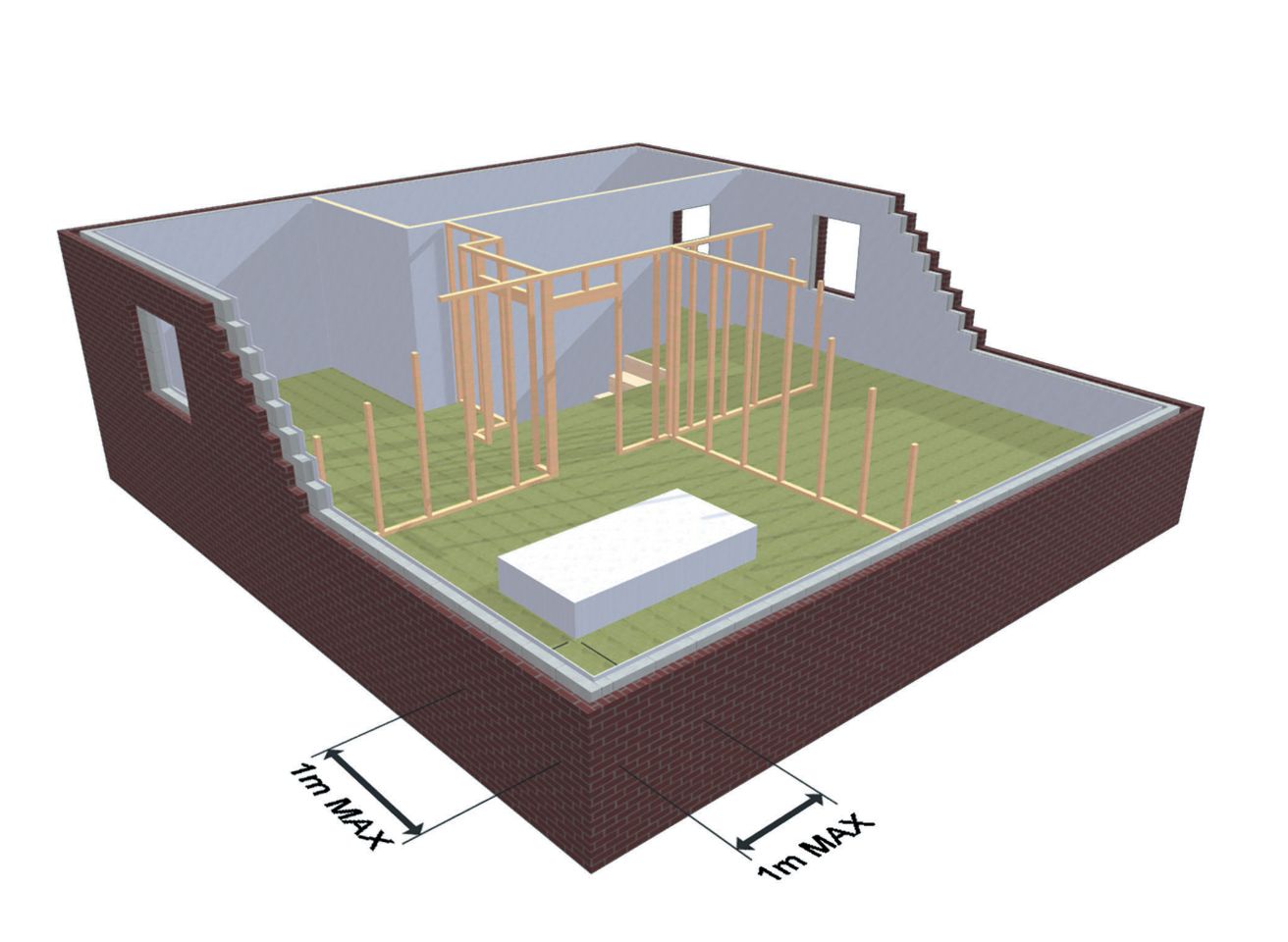

A single stack of plasterboard or chipboard, laid flat, may be loaded out on the floor no further than 1m from external walls, provided it is no higher than 450mm for chipboard or standard plasterboard or 350mm for all other plasterboard types.

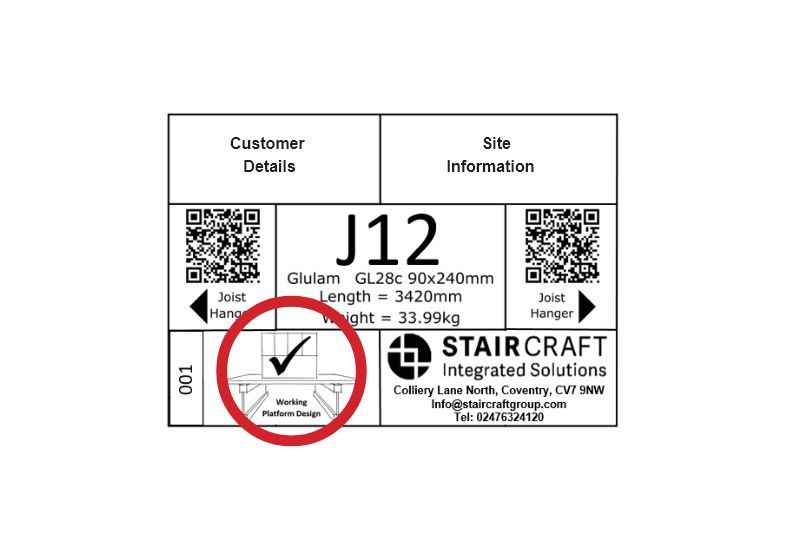

Without this logo on the joist labels and the floor design plan, the floor will need back-propping before being used as a working platform.

This logo will be visible on the joist labels and design plans of floors designed to support the requisite construction loads without the need for back-propping.

The limits given in this guidance on the positioning and amounts of concrete blocks, chipboard or plasterboard sheets must be adhered to. No provision is made for construction materials to be placed on the floor in their original (as delivered) packaging or pallets

Use timber boards, pallets or ’skids’ to keep moisture sensitive materials off the deck to allow for ventilation and be clear of localised ponding.

Using an un-propped i-joist floor as part of a Staircraft working platform still requires Health and Safety planning.

The Principal Contractor should always plan the use of the floor with due consideration to the following

Planned use of the floor during the construction phase should be referenced in method statements and risk assessments.

The use and limitation of the floor should be communicated to all relevant personnel involved during the construction phase. This may take form of clear signage and/or referenced during the site induction process.

For any further information on this or other details which are unique to Staircraft